Rolex watches have long been a marker of luxury and status. The internationally renowned watch brand’s reputation precedes itself. Have you ever wondered where these beautiful and elegant timepieces are made? Continue reading to learn more about the brand and where Rolex watches are made.

Rolex Production Locations

Rolex watches continue to be a standard for luxury. It is a status symbol and for some might be considered a sign of exquisite taste. Every step of the manufacturing process by the brand allows control over the most minute details, which is why fake Rolex reproductions continue to produce flawed designs. While some might be under the impression that a Rolex is produced in one single building that may not be the case. The brand continues to remain a Swiss company, but the company operates from a number of different locations in Switzerland.

Les Acacias, Switzerland – The Rolex Headquarters

The Rolex international headquarters is located in Les Acacias, Geneva. It was constructed in 1965 and features the brand’s trademark Rolex green colors. All departments of the Rolex process are housed here. This includes management, research and development, design, communications, sales, customer service, parts assembly, and quality control.

At Les Acacias, each Rolex product made undergoes a rigorous quality control process. This process maintains the brand’s high standards. All Rolex watches produced at the headquarters go through testing for self-winding, waterproofness, and precision.

This plant is where the final assembly of all Rolex watches takes place. All components are delivered by the three other sites. Once the final quality control process is completed the watch receives the Green Rolex Seal and a five-year guarantee.

Bienne, Switzerland

The Bienne production facility used to be the home of the Aeglar Company. The Aeglar Company made the high-quality calibers found in Rolex watches. In 2004, Rolex purchased the company in a notably large acquisition. There are approximately 2,000 workers focused on producing the inner workings of a Rolex watch. This includes the calibers, patented Paraflex shock absorbers, and Parachrom balance springs.

Precision is of the utmost importance at this plant. All components are manufactured of the order of a few microns. It is important to stay compliant with the criteria of the Swiss Official Chronometer Testing Institute (COSC). Rolex’s quality control helps each watch meet this standard.

Expertly trained operators and watchmakers handle all assembly. Additionally, the assembly of each Rolex watch is done by hand.

Plan-les-Ouates, Switzerland

Plan-les-Ouates is located within Geneva and handles the accessory portion of the Rolex production process. This plant specifically handles cases and bracelets for the entire Rolex line. The Plan-les-Ouates facility is the largest of the Rolex production line. This 11-story facility has six of those stories underground for maximum protection. It is composed of six wings linked by a central axis.

This site houses a state-of-the-art robotic inventory lab, security scanners that can scan your iris for entry, and Rolex’s famed pirate gold foundry. This foundry helps produce the brand’s three types of gold: yellow gold, white gold, and Everose gold. The Everose type is Rolex’s proprietary pink gold that many of its wearers have fallen in love with. All of the company’s 904L stainless steel is also produced at the Plan-les-Ouates location. There is a top-rated ceramics department in this facility as well.

From casting the gold and forming the raw materials to the machining and polishing of the finished components, this plant is tasked with an integral part of the production process.

The attention to detail is reinforced at this plant with a team of scientists studying elements like lubrication, wear, and friction of various metals and how they can affect Rolex watches over time. These scientists apply their findings to the watch production process in order to help improve how Rolexes are made.

Chene-Bourg, Switzerland

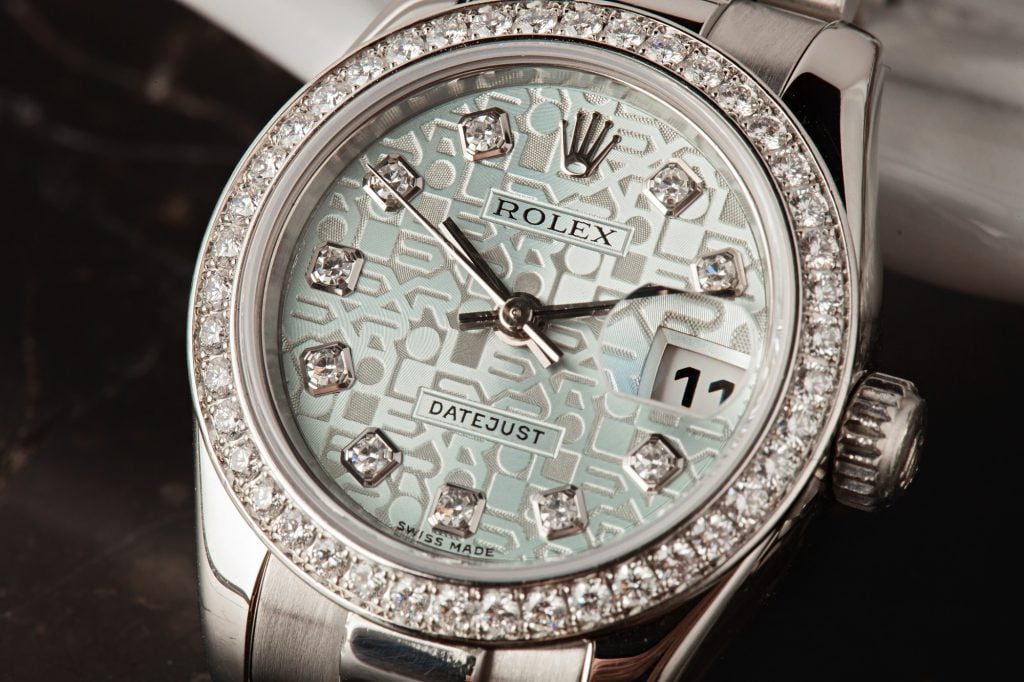

The Chene-Bourg facility is responsible for the dial and gem-setting for the Rolex brand. Rolex is very strict when it comes to their gemstones, only selecting flawless items to be used in their pieces. The high-quality precious stones hand-placed on Rolex watches add to their unique brilliance and careful setting. All dial markers are made from solid gold. Any watch cases that are produced at this facility are hand-polished to put the finishing touch on each item.

This is where the Rolex watches begin to take final shape with the careful and intentional placement of various flawless gemstones throughout the band and watch face. The combination of state-of-the-art technology and human expertise creates a unique production process that encapsulates Rolex’s commitment to quality and attention to detail.

Masters of Waterproofness

When Hans Wilsdorf set out to create the perfect watch, one of the biggest challenges was finding a way to protect from dust and moisture. Dust and moisture can cause problems like clogging and oxidization if they happen to infiltrate the watch’s casing. Together with the help of Aegler, the company in Brienne that would become the primary Rolex manufacturer, they developed a waterproof wristwatch to meet the challenges of everyday wear and tear.

The Submarine, created in 1922, was the first of these efforts. It was the first of its kind by being attached to a hinge inside a second, outer case. This outer case utilized bezel and crystal screwed down in order to create a watertight seal. The Submarine was Wilsdorf’s first step towards producing a waterproof watch.

The Oyster Case

The Submarine’s dual-case design became known as the Oyster Case and was patented as such in 1926. Its design and winding movements ensured a hermetical seal that protected the watch’s inner chamber from the outside elements. The name came from the animal itself, with Wilsdorf citing its ability to remain underwater as long as it wanted without the water damaging its parts.

Wilsdorf decided to put his creation to the test in a way that only Rolex could pull off. He learned that Mercedes Gleitze was about to set a world record by becoming the first British woman to swim across the English Channel. He asked her to carry an Oyster with her along the journey to show its durability and waterproofness. Upon finishing the swim, the Oyster was revealed to have kept good time and made a statement to all.

The Bezel

The bezel for the Oyster watch was fluted, meaning it could be screwed down onto the middle case using a special tool that was exclusive to Rolex watchmakers. As time went on, so did technological advancements in the world of watchmaking. The bezel eventually advanced to the point of it being possible to become rotatable and fitted. This design became very popular with divers’ watches.

The Case Back

A fine fluting technique is applied to the back of the Oyster case, which allows it to be screwed down hermetically at the middle case. Many of the current divers’ watches in the Rolex inventory have a case back made up of either Oystersteel or 18 kt. gold.

The Crown

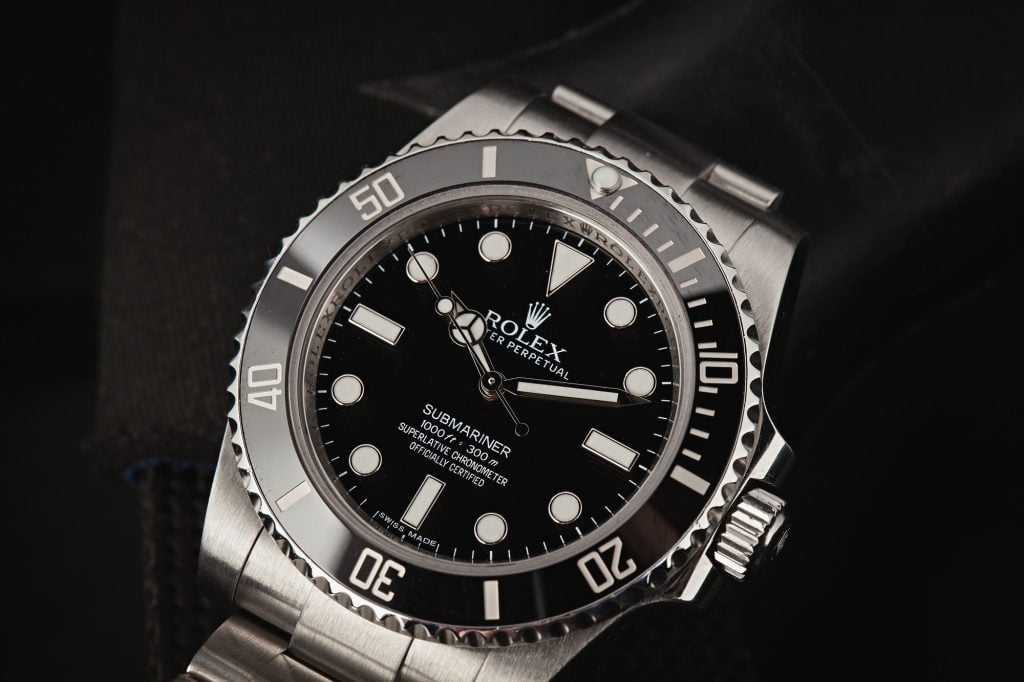

On the original Oyster case, the crown was screwed down onto the middle case. Rolex later introduced the Twinlock winding crown in 1953. It was this year that the famous Submariner watch was launched, becoming a staple in the divers’ watch category that still sits atop the throne to this day.

This system featured a patented double seal. Later, in 1970, the system was yet again enhanced with an additional sealed zone that reinforced the waterproofness of the product.

Tested to Meet All Quality Standards

Rolex has a reputation to uphold, which is why each of its products goes through rigorous testing protocols before being bestowed with the famous Green Seal.

The modern Oysterlock system, fitted on most Professional Rolex models, undergoes 26 different types of drop tests before leaving the production facility. This helps to ensure protection against accidental knocks and gestures as well as climbing summits with altitude or diving down to great depths with pressurization.

The clasp system is tested by submerging the watch in a tank of chlorine and salt water. Sand is then added to the mixture and the clasp is opened and closed tens of thousands of times to ensure smooth functionality with each locking and unlocking.

In addition to the Oysterlock system, all Rolex watches are tested for chronometric precision of its cased-up movement, self-winding functionality, and power reserve. All of these elements combine to make the Rolex product that is so revered among the watch community.

With Rolex, Quality Breeds Quality

As you can see, Rolex has taken every measure to ensure the quality standards of its brand. The multi-pronged approach to watchmaking uses several production facilities, each of which is assigned a specific task. This allows each plant to excel in a specific criterion rather than muddying the quality by combining areas.

The amount and type of testing that goes into each watch show Rolex’s care for their finished product. While these watches are known for their luxury, their namesake is in the watches’ reliability and functionality. The testing that goes into these watches guarantees that your Rolex will stand the test of time and work just as well as when you opened it and put it on for the first time.

Shop for Your Next Rolex Now

At Bob’s Watches, we carry many different Rolex watches. Our customer service team is happy to assist in answering your questions and helping you find the perfect Rolex for you or a loved one. Contact us today for help or browse through our online inventory now.

Comments are closed.